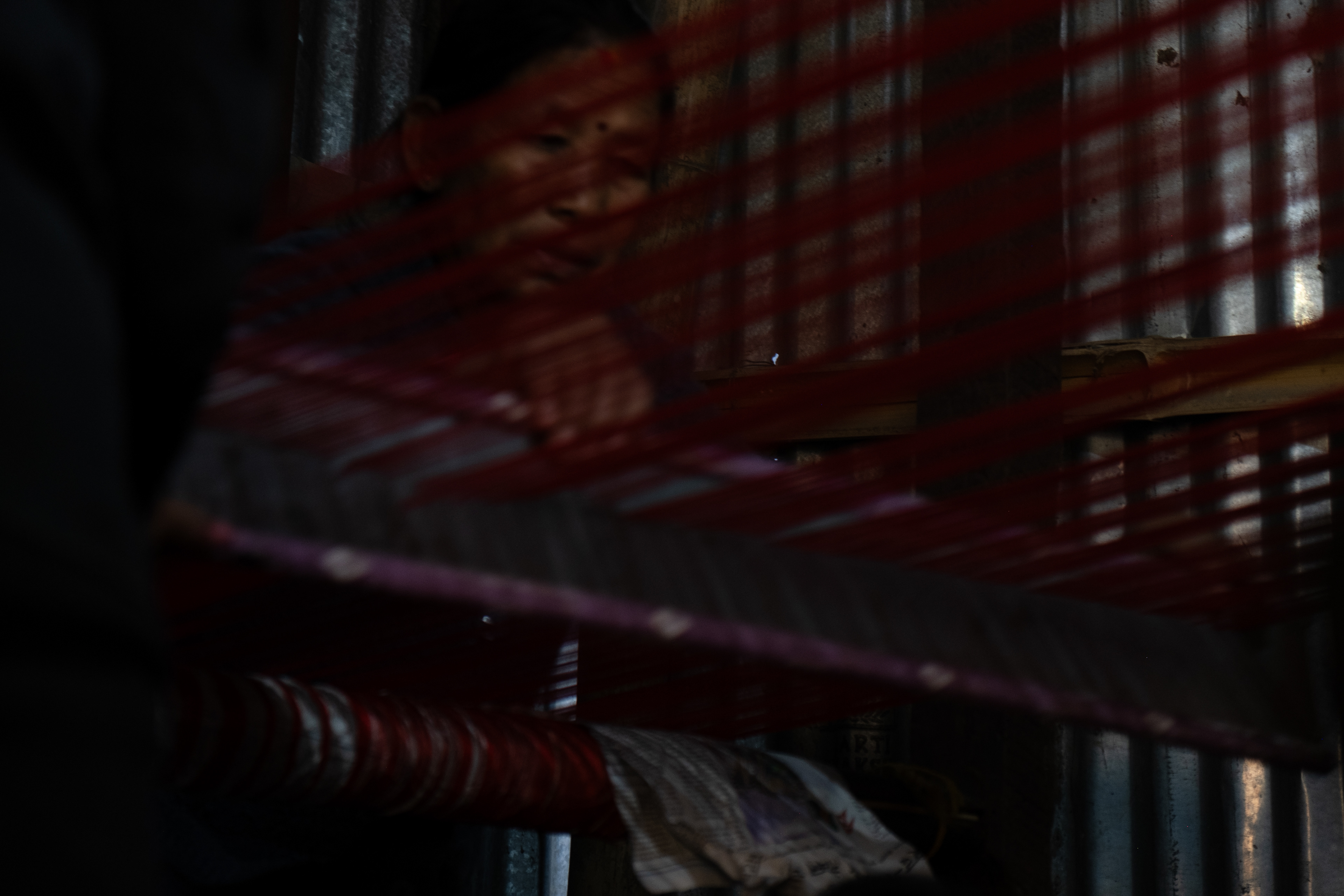

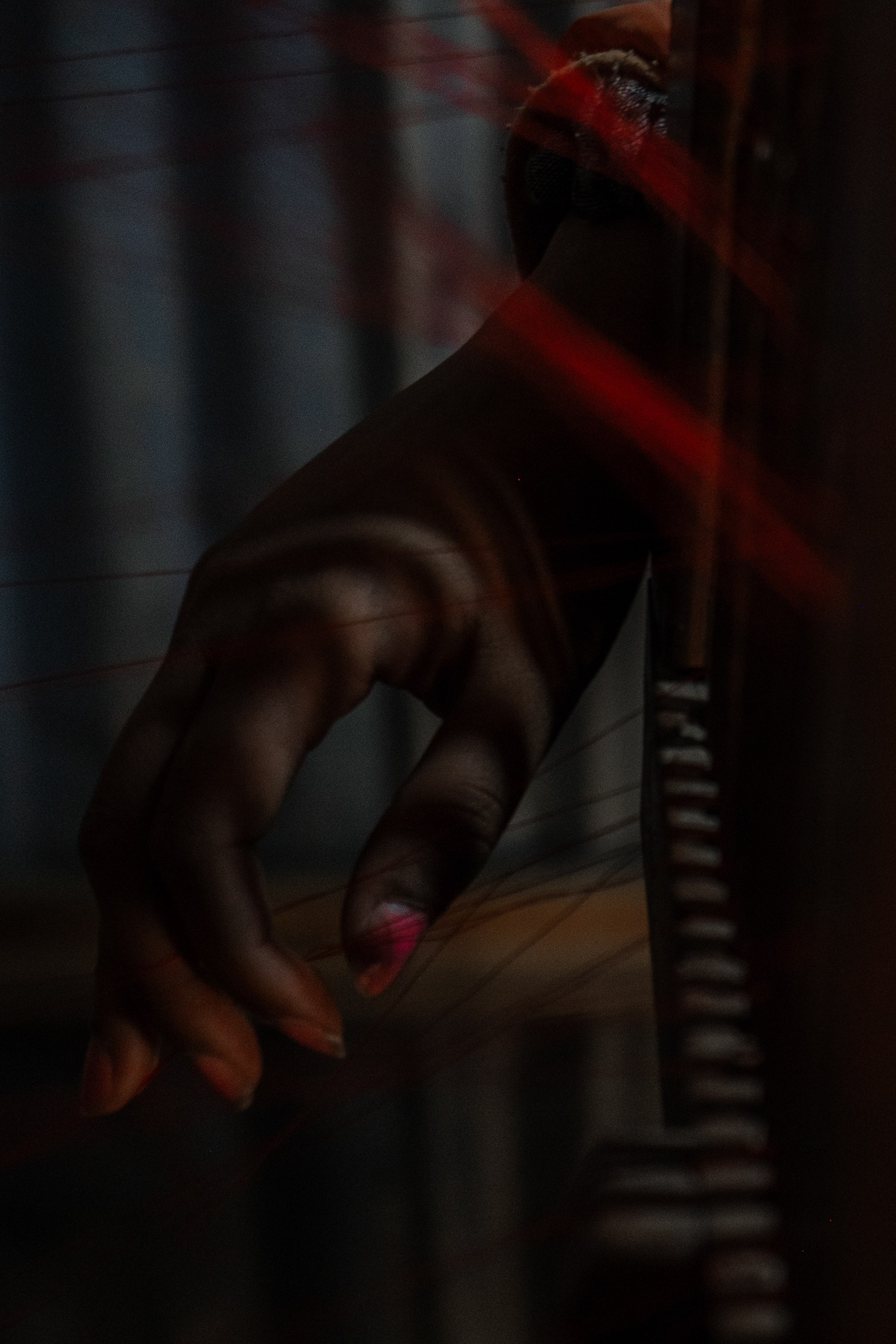

As you enter the shed of corrugated tin, the darkness and the warmth of the dense air welcome you. The bright daylight is trying to break through the cracks where the walls meet the ceiling. All you can hear is the wooden looms silently working in rhythms of treading. The pedals creak concurrently with the steps of a woman in deep concentration. Tsk – tsk. Click, clack. Shh.

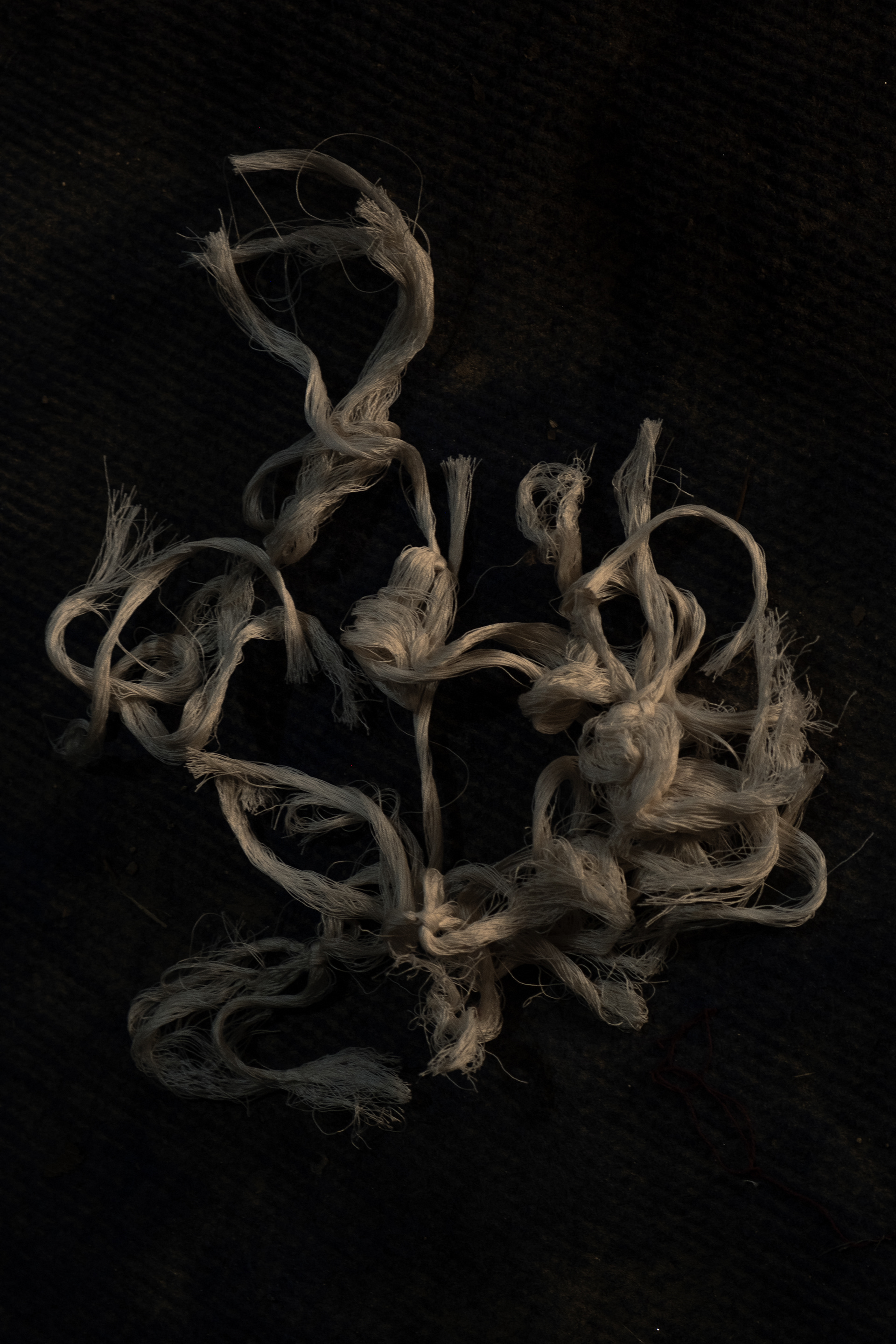

The weaving of fabrics is an old Nepali tradition. Saris, handkerchiefs, scarves. Weaving provides work. Work for women who need it to provide for themselves and their families. Manisha (20) wants to use her science education to expand her aunt’s business. The weaving factory is dependent on imported materials from neighboring coun- tries. Manisha aims to create a sustainable business using only Nepali products. A significant challenge the industry faces is the increasing usage of automated weaving machines, leading to job losses. Efficient- ly machine-made products will replace high-quality handmadetextiles.

“If I continue to do this work, and we expand by recruiting more workers, this will also mean improving the work environment in the future. Hopefully, we’ll defeat the machines in the end”, Manisha says.